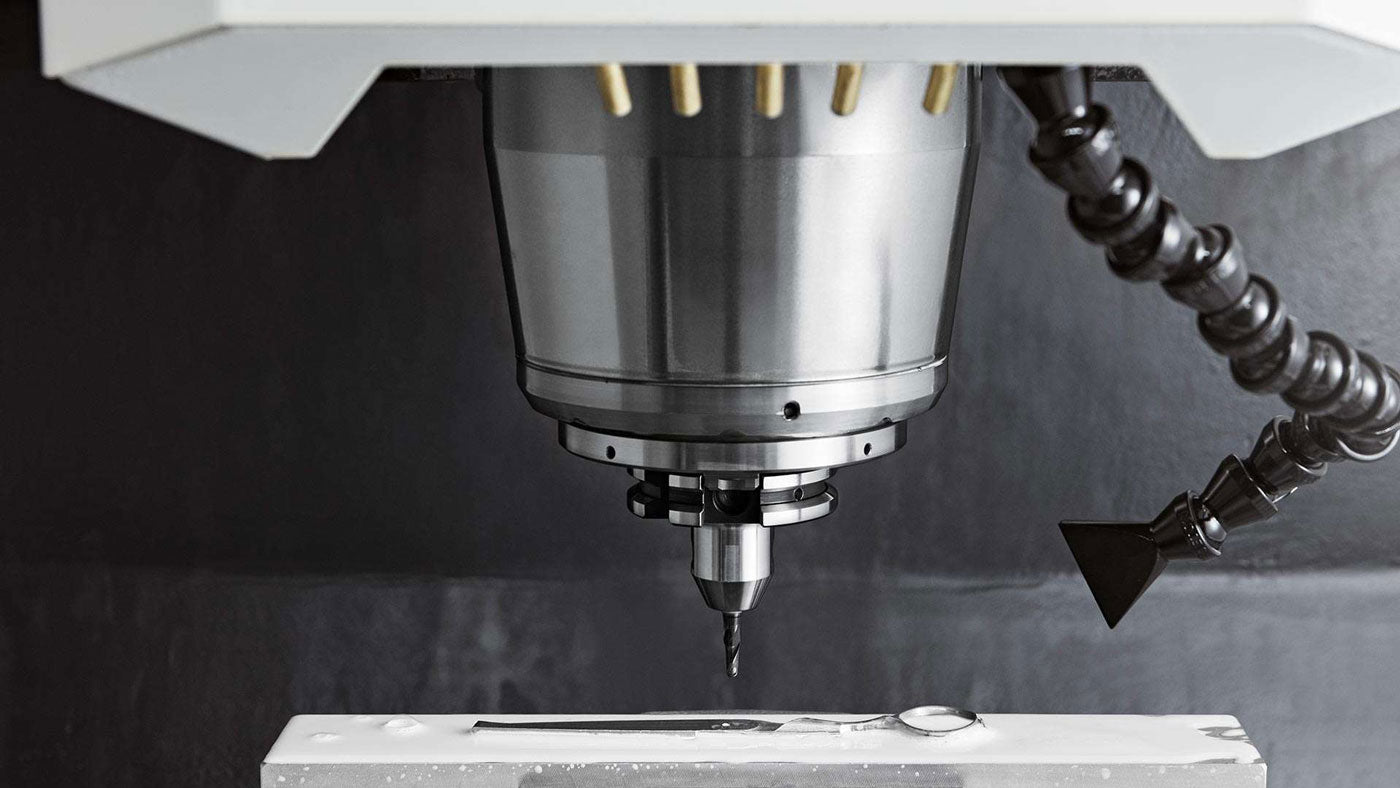

Precision from a single source

Most scissors worldwide are manufactured using a modular design, meaning that the handle and cutting edges are welded together from separate parts before forging. In contrast, TONDEO is the first and so far only scissors manufacturer in the world to use CNC technology to mill the highly precise blanks for the scissors entirely from a single piece of steel.

Finely structured steel for effortless cutting

Unlike forging, milling does not involve repeated heating and cooling of the steel. This prevents the steel structure from being altered or stressed. This allows the steel to retain its fine and uniform structure. The desired material properties, such as hardness and edge retention, are also retained.

Thanks to this unprecedented precision, TONDEO's scissor sharpeners and inspectors, with their immense expertise, are able to reduce the required closing force to as little as 10 grams. This translates into enormous energy savings for the hairdresser over the course of a year.

Preserve what is proven, make what is good better.

Because we believe that good things can be made even better, we at TONDEO work tirelessly to optimize all production processes. We want to further optimize the careful use of our resources and achieve even smoother handling and even greater sharpness and stability for our premium products.

Efficient production

Thanks to our globally unique milling technology, we work with a blank with precise contours, allowing us to produce in a resource-efficient manner. Adding material is unnecessary; the steel chips created during milling can even be recovered and recycled back into the process.

Sustainable innovation

To ensure our high quality standards continue to be met in the future, we continually review our processes. This enables us to always be at the cutting edge of technology. This allows us to continuously reduce energy consumption, material consumption, CO2 emissions, transport routes, and much more.